PRODUCT LOAD RATINGS AND DOCUMENTS

Information & Definitions on Quarantine Load Ratings

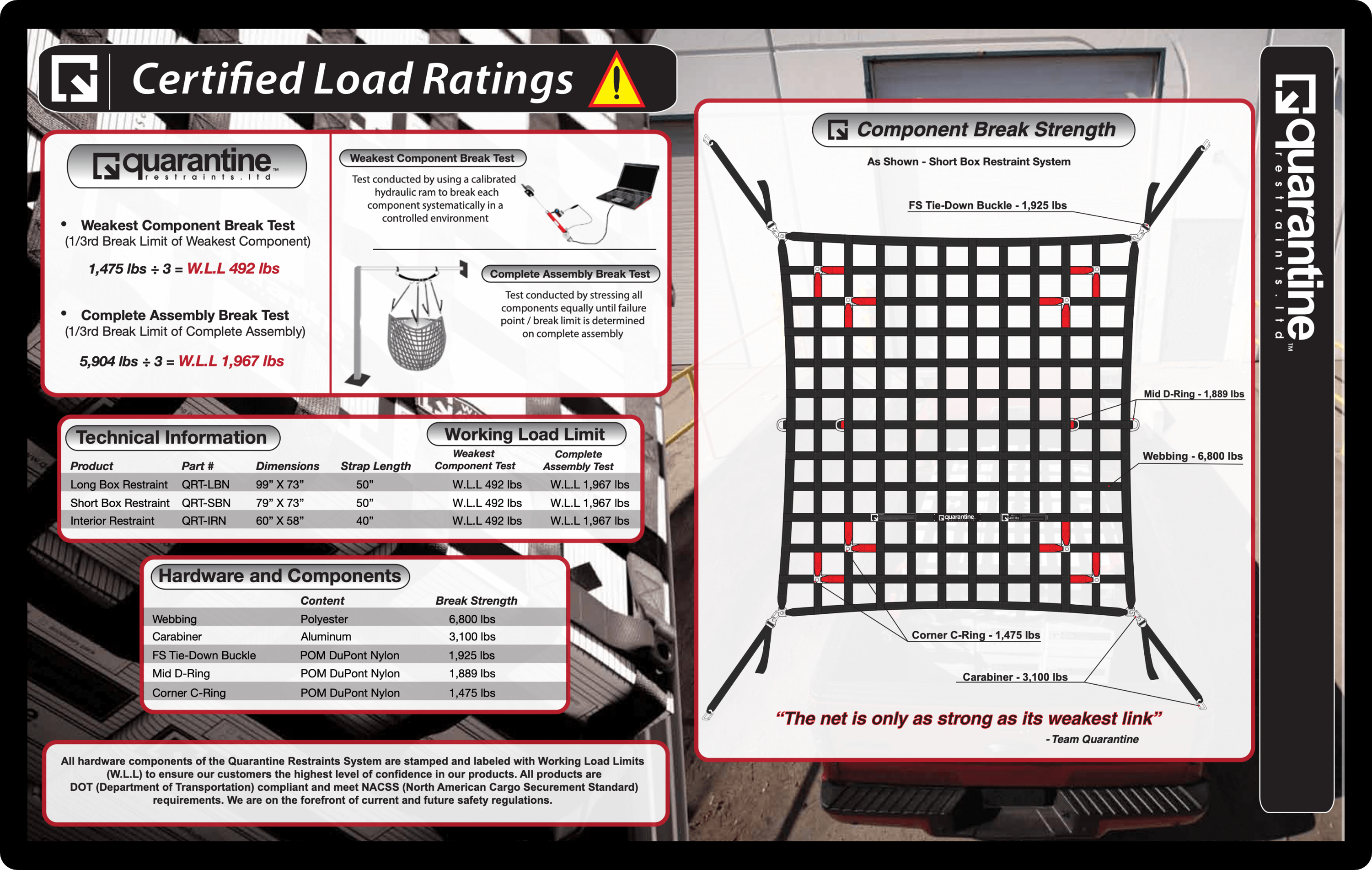

Weakest Component Break Test:

Conducted by using a calibrated hydraulic ram to break each component systematically in a controlled environment.

Complete Assembly Break Test:

Conducted by stressing all components equally until failure point. For this test the break limit is determined on complete assembly.

Break Limit:

Determined by the amount of tension, pressure or weight it takes to “break” any component.

Safety Factor:

To determine the Working Load Limit (WLL) rating of a cargo net, sling or tie down, a Safety Factor is used. This number is set by the industry and is divided into the break limit of the product. Three is the industry standard Safety Factor for rating a cargo net, sling or tie down.

Break Limit ÷ 3 = Working Load Limit (WLL) A Safety Factor of 3 is the standard for complying to NSC 10 legislation and the industry standard for rating a cargo net, sling or tie down.